hpo Spotlight Industrial Performance

Business excellence through organisational and operational performance improvement

Continuous development is essential for companies in the industrial sector. It is the only way for them to survive in a challenging, competitive environment and to be successful in the future. However, changes are often only made in isolation: Companies either focus on improvements in production or on optimising their business processes. However, optimising just one of these areas is not enough. To achieve a real breakthrough in performance, production processes and the company’s organisation must be aligned. Only when production and business excellence are advanced together, industrial companies can make the decisive leap in performance.

Share article

The demands on manufacturing companies in European high-wage locations are increasing rapidly. Sustained competitive and cost pressure, economic fluctuations, increasing complexity, material bottlenecks, and a shortage of skilled labour require the highest levels of performance and flexibility. However, more efficient production on its own is not enough. Companies often find that efficiency measures only have a superficial effect and that productivity, EBIT, and market performance remain unchanged.

The issue can be change initiatives that fail to take into account the complex interdependencies between production and organisational processes. Isolated changes in individual areas often fail to achieve the desired effect. The negative consequences of this are first felt at the employee level and then become apparent in the company’s economic success.

Improvements in industrial companies never take place in isolation

hpo tackles these challenges together with its clients by approaching every adjustment in the factory or administration building with a holistic mindset. Experience shows that transformations are only successful if they anticipate cross-departmental dependencies and represent a holistic solution.

However, it is not only large-scale transformations that require a company-wide perspective. Even clearly defined change initiatives are usually not solvable from an isolated perspective. Successful change projects in industrial companies are characterised by the fact that they simultaneously strive for excellence in manufacturing and business processes. The result can be seen, for example, in the following aspects:

- Consistent standardisation

Standardisation is driven forward by engineering in close cooperation with sales, production, and industrialisation. Clear roles and responsibilities in the relevant business processes ensure that development takes place efficiently and in line with market requirements, It is also supported by the sales department in relation to customers.

- Holistic processes

Production and business processes are developed in line with one another to ensure the highest process performance. A core team made up of representatives from all steps of the value chain works with the hpo team to design the corresponding process models and supports their implementation throughout the organisation.

- Coordinated shop floor management

Other areas, such as engineering, industrialisation, and sales are involved in regular meetings with production. Learning loops run through the entire organisation and identify root causes and, thus, the potential for improvement in a targeted and efficient manner.

- Targeted performance measurement

Measuring performance in the production hall is an integral part of the company-wide KPI structure. Improvement initiatives in all areas are coordinated across functions and contribute to the same strategic goals.

Improvements in business processes and production must go hand in hand

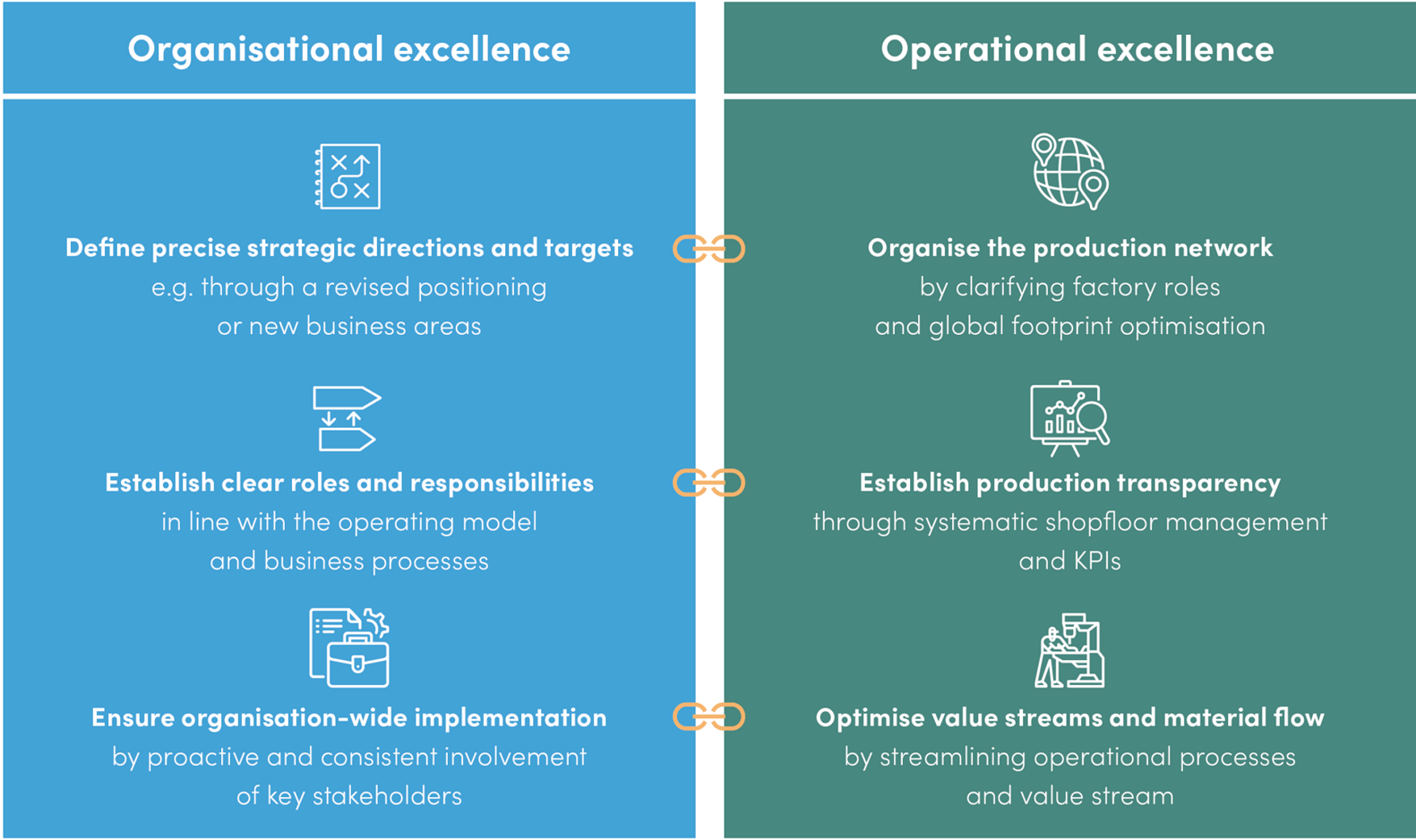

The target picture above clearly shows that improvements in production and other areas of the company must be organised together. hpo’s holistic approach aims to actively involve everyone who can influence the success of an improvement initiative in the development of the solution. This often includes departments that are not the focus of the initiative. Key people in the affected functions actively help to shape solutions and are involved in the decision-making process. The entire workforce is communicatively involved.

Another critical success factor for business excellence is that processes and organisation are consistently aligned with the strategic direction. As the diagram shows, a transformation begins with the target image being adapted or sharpened across all functions. Transparency must also be ensured on the shop floor to measure success. The subsequent optimisation of the organisation ensures clear roles and responsibilities throughout and is a further basis for redesigning the production and logistics network.

Organisational excellence + operational excellence = Business excellence

Business excellence in industry requires a simultaneous increase in organisational and operational efficiency.

hpo’s approach anticipates and addresses areas of tension in change initiatives. Solutions are not transferred in a cookie-cutter fashion but are sensitively adapted to the respective initial situation. Cross-functional core teams support transformations in terms of content and communication. In particular, a bridge is built between production and other parts of the organisation. This creates a motivated team with the necessary competency profile that stands behind the common goal, preventing unnecessary course corrections and therefore costs, additional effort, and uncertainty.

Result: Increase in EBIT and productivity by 10 to over 20 percent

hpo has been supporting industrial companies whose challenges can only be solved with a cross-functional perspective. This includes seemingly isolated issues such as improving the flow of goods or the sales performance of a product group - but also those with a cross-departmental impact, such as international relocations of production lines or site consolidations.

Properly implemented, such initiatives bring sustainable increases in performance, as various reference projects show:

Increased earnings:

In a major transformation programme at a specialist machinery manufacturer, improved shop floor management and value stream design, accompanied by the improvement of company-wide end-to-end processes, resulted in a year-on-year EBIT increase of over 10 %.

Productivity increase:

A production optimisation initiative at a medium-sized Swiss company, accompanied by the establishment of an industrialisation department, led to an increase in personnel productivity of over 20 %.

Reduction in material costs:

In several projects, material costs was reduced by around 10 % through standardisation and simultaneous process improvements in procurement.

Reduction in logistics costs:

Consolidating the logistics of a component manufacturer in a European warehouse while simultaneously adapting the organisational control mechanisms led to potential cost savings of around CHF 10 million.

The potential for your company can be identified in a performance assessment. With the hpo approach, improvements are effective in the long term.

hpo – your partner for industrial performance

hpo combines decades of industrial experience with a holistic and partnership-based approach to creating solutions. Our satisfied custom¬ers include global market leaders and hidden champions in Switzerland, the DACH region and beyond. Our principle of having those affected take part in the development of solutions strengthens the process and development capability of organisations. It leads to demonstrable and lasting performance improvements.

Interested in finding out how the potential in your organisation can be unleashed?

Contact us for a no-obligation assessment.

Volker Schemmann

Associate Partner